Technology

We provide safer, faster-charging, and longer-lasting batteries

We provide safer, faster-charging, and longer-lasting batteries

through outstanding technology capabilities.

Manufacturing Process

Electrode |

|

Cell Assembly and |

|

Module Assembly |

|

Pack Assembly |

Core Technology

Safer than EVer

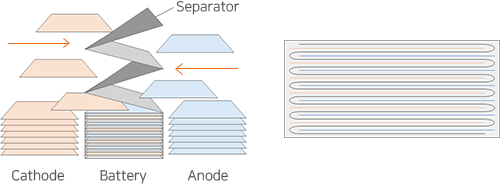

Z-folding Technology

We have exclusive ownership of a stacking method that intersects and stacks cathodes and anodes between the separators in a zigzag shape to achieve the highest level of safety. The Z-folding technology minimizes cell stress and evenly stacks cathodes and anodes to prevent physical contact between electrodes, greatly reducing the potential risk of internal short and ignition of our batteries. In addition, the technology allows stable alignment between anodes and cathodes, and thus further improves safety. We have secured the highest level of aligned electrode manufacturing technology in the world in terms of high-speed stacking, which allows us to offer improved safety despite the acceleration of battery process production speed.

Faster than EVer

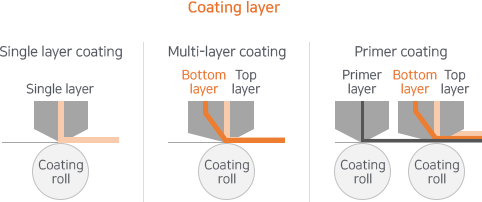

Coating Technology

In comparison to traditional single layer coated electrodes, our proprietary technology implements two separate layers with different electro-chemical properties. Dual layer coating offers multiple advantages, including the lowering of binder content near the surface which significantly increases lithium-ion conductivity during charging cycles. Moreover, we secured the multi-layer coating (MCS) technology and primer coating technology by continuously developing the binder coating process, which allow us to improve the high-speed charging speed significantly compared to single layer coating technology.

Longer than EVer

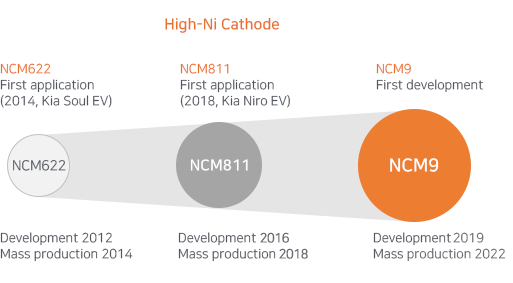

Materials Technology

By using high-nickel cathode materials, we maximized energy density and secured superiority in terms of capacity, thermal safety, and cycle performance compared to existing batteries. Ever since NCM622 battery was supplied to electric vehicles for the first time in the world in 2014, we set a new industry standard through the NCM811 and NCM9½½. Going forward, our goal is to reach an energy density of 1,000 Wh/L or higher. In addition, we are working to extend drive range through module technology that maximizes spatial efficiency inside batteries as well as next-generation battery technology including silicon anode materials.

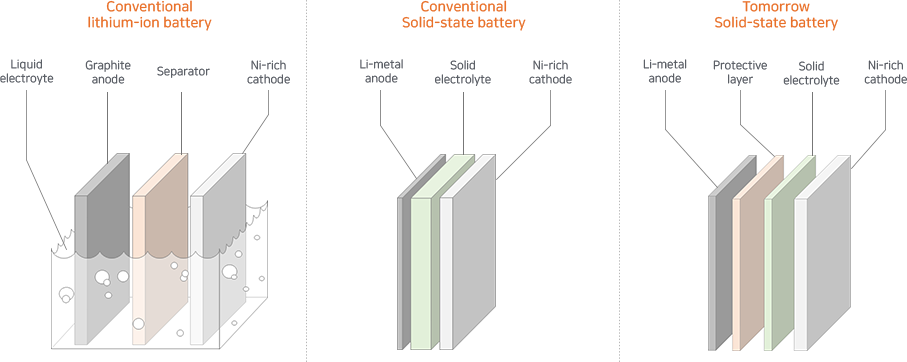

Next Generation Battery

We put great efforts and ceaseless R&D investment in future battery technology along with lithium-ion batteries. We focus on our R&D capabilities to commercialize next-generation batteries, including solid-state batteries with great energy density and safety, and are advantageous for high-speed charging compared to lithium-ion batteries.